Common Causes of Valve Failure in Industrial Systems (And How Materials Can Help)

Valves may be small compared to pumps, exchangers, or full process lines—but when they fail, the impact is anything but minor.

Whether you’re in chemical processing, oil & gas, mining, marine, or power generation, valve failures can trigger production downtime, safety hazards, and costly maintenance headaches. And while poor installation and lack of maintenance are often to blame, the root cause frequently comes down to material selection.

At PM International, we’ve seen this story play out across industries for decades. Here’s a closer look at the most common causes of valve failure—and how choosing the right materials can prevent them from happening in the first place.

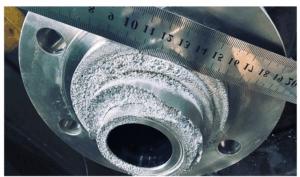

1. Corrosion: The Silent System Killer

Corrosion is easily the #1 culprit behind valve failures in industrial environments. This includes:

- Uniform corrosion in acidic environments

- Pitting and crevice corrosion in chloride-rich or marine conditions

- Galvanic corrosion from mixing dissimilar metals

How Materials Can Help:

- Titanium (Grades 2 & 12): Excellent for chlorides, acids, and seawater

- Copper Nickel (90/10 & 70/30): Ideal for saltwater and brine

- Aluminum Bronze: Great resistance to biofouling and seawater corrosion

These materials outperform stainless steel or carbon steel valves in aggressive chemical and marine applications.

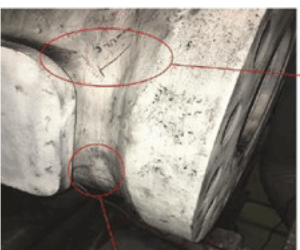

2. Erosion and Cavitation: High Flow, Big Problems

High-velocity fluids, suspended solids, or pressure drops across valve seats can cause internal erosion or cavitation damage over time. This is especially common in:

- Slurry systems in mining

- Cooling systems in marine vessels

- High-pressure lines in refineries

How Materials Can Help:

- 70/30 Copper Nickel: Superior resistance to velocity-driven erosion

- Titanium Grade 12: Strong under turbulent flow and heat

- Forged Titanium: Better wear and cycle durability in throttling valves

3. Thermal Fatigue and Creep

Industrial systems often run hot—and cycle between hot and cold frequently. Over time, this thermal cycling leads to material fatigue, cracking, or creep (permanent deformation).

How Materials Can Help:

- Titanium Grade 12: Excellent high-temp performance and structural integrity

- Specialty Alloys: PM International can source to match NORSOK and EN specs for high-temp applications

4. Using the Wrong Material to Begin With

This one’s more common than most teams would like to admit.

Using a “standard” stainless or carbon steel valve because it’s cheaper or easier to source may save money today—but could cost exponentially more in the long run. We’ve helped clients who faced premature valve failures simply because the material didn’t match the media or environmental exposure.

What to Do:

- Work with a supplier (like PM International) that understands your operating conditions

- Don’t just match pressure and size — match media compatibility, flow characteristics, and temperature

5. Seat Damage and Mechanical Wear

Valve internals—especially seats—can be worn down by abrasive flow, frequent cycling, or particles in the process fluid. Once wear begins, it often accelerates rapidly.

How Materials Can Help:

- Hard-wearing materials like forged titanium extend service life

- Aluminum bronze or 70/30 copper nickel seats can reduce internal galling and seizure

- Customized valve solutions with reinforced seats or coatings are also available

Real-World Example: A $1M Switch That Paid Off

In 2024, a distributor working with a major Gulf Coast facility needed to replace failing valves used in a high-chloride application. The original spec used stainless steel ball valves, which began leaking and corroding within months.

PM International stepped in with a solution: forged titanium valves custom-built to spec and compliant with ASTM standards. The $1M valve order not only resolved the issue—it tripled the expected lifespan and eliminated recurring maintenance costs.

Why Teams Rely on PM International for Valves

At PM International, valves aren’t a side product—they’re a core focus of what we do. Our customers count on us for:

✅ Corrosion-resistant valves in titanium, copper nickel, and aluminum bronze

✅ Forged and cast valves available in gate, globe, check, and plus configurations

✅ Short lead times, global sourcing, and NORSOK/ASTM-compliant specs

✅ Expert guidance on material selection and real-world performance

We don’t just move metal—we help prevent failure.

Let’s Prevent the Next Downtime Before It Starts

Whether you’re designing a new system or troubleshooting an aging one, the right valve material can make all the difference. Let us help you find the solution that fits your exact environment, specs, and budget.

👉 Request a Quote, chat or call PM International today to speak with a valve expert.