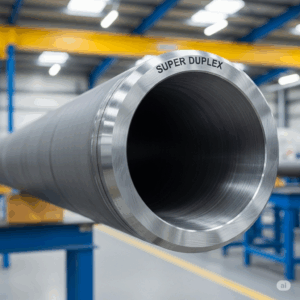

What is Super Duplex Pipe?

Super Duplex pipe refers to a high-performance piping product made from super duplex stainless steel—an alloy that combines the best properties of both austenitic and ferritic stainless steels. These pipes are renowned for their exceptional strength, superior corrosion resistance, and resistance to stress corrosion cracking, making them ideal for demanding environments like offshore oil rigs, desalination plants, and chemical processing facilities.

TL;DR (Too Long; Didn’t Read)

Super Duplex pipe is a high-strength, corrosion-resistant pipe made from austenitic-ferritic stainless steel. It’s ideal for industries like oil & gas, marine, and desalination.

What Is Super Duplex Stainless Steel?

Super duplex stainless steel is a dual-phase alloy composed primarily of:

– Iron (Fe)

– Chromium (Cr) – typically 24–26% for corrosion resistance

– Nickel (Ni) – enhances toughness and corrosion resistance

– Molybdenum (Mo) – improves resistance to pitting and crevice corrosion

– Nitrogen (N) – increases strength

These elements create a 50/50 microstructure of austenite and ferrite, which delivers a unique combination of mechanical strength and corrosion resistance—often outperforming standard duplex and many nickel alloys.

Key Features of Super Duplex Pipe

– High Strength: Approximately twice the yield strength of austenitic stainless steels like 316L.

– Outstanding Corrosion Resistance: Performs exceptionally in chloride-rich and acidic environments.

– Stress Corrosion Cracking Resistance: Ideal for high-pressure, high-temperature systems.

– Toughness: Maintains impact resistance even at sub-zero temperatures.

– Cost Efficiency: Offers performance similar to high-nickel alloys at a more competitive price point.

How Is Super Duplex Pipe Manufactured?

PM International Suppliers provides super duplex pipes in both seamless and welded forms:

Seamless Pipes

Produced via extrusion or hot piercing, seamless super duplex pipes offer:

– Consistent mechanical properties

– Smooth internal and external surfaces

– Ideal for high-pressure applications

Welded Pipes

Formed from super duplex plate and welded longitudinally:

– Available in larger diameters and heavier wall thicknesses

– Cost-effective for lower-pressure systems or where longer lengths are required

We also offer NORSOK-compliant material and traceable heat treatment certificates, ensuring quality for every project.

Applications of Super Duplex Pipe

Because of their unique properties, super duplex pipes are used in:

– Oil & Gas: Subsea pipelines, risers, manifolds

– Desalination: High-resistance to chlorides

– Chemical Processing: Acidic and high-temp environments

– Marine Engineering: Hulls, ballast systems, and cooling systems

– Pulp & Paper: Chloride bleaching stages

– Power Generation: Heat exchangers and pressure vessels

Available Sizes & Standards

PM International Suppliers offers super duplex pipes in:

– Standards: ASTM A790, ASME SA790, EN 10216-5

– Grades: UNS S32750 (1.4410), UNS S32760, and others

– Sizes: From ½” to 24” diameter

– Wall Thickness: SCH 10 to XXH and custom specs

Need a custom cut or tight delivery schedule? We work with mills worldwide to accommodate your unique needs.

How Does Super Duplex Compare to Other Alloys?

| Alloy Type | Yield Strength | Corrosion Resistance | Typical Use Case |

|---|---|---|---|

| 316L Stainless | Low | Moderate | Basic corrosion protection |

| Duplex (S31803) | Medium | High | More strength, moderate cost |

| Super Duplex | High | Very High | Harsh, corrosive environments |

| Inconel 625 | Very High | Extreme | High-temp, aggressive media |

Common FAQs

Q: Is Super Duplex better than 316 or 304 stainless steel?

A: Yes—super duplex offers 2x the strength and much higher resistance to pitting, cracking, and corrosion.

Q: Can I weld super duplex pipe?

A: Yes, but it requires controlled procedures to maintain phase balance and corrosion resistance.

Q: Is super duplex magnetic?

A: Yes, due to the ferritic phase, it is partially magnetic.

Where to Buy Super Duplex Pipe

PM International Suppliers is a trusted source for super duplex pipe, flanges, fittings, and custom-cut lengths. We supply worldwide and are experienced in meeting offshore, NORSOK, and ISO specifications.

👉 Contact us today at [email protected] or request a quote directly on www.pmfirst.com.