Understanding Stainless Steel Hardness: What It Means and Why It Matters

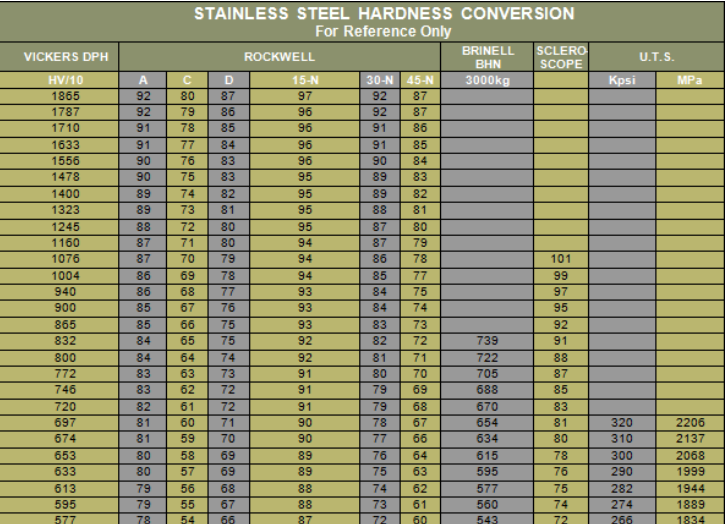

When you’re selecting stainless steel for an industrial application, hardness is more than just a number on a spec sheet — it directly affects how your component will perform in the real world. (See our hardness chart here or click the image below)

Whether you’re building a piping system, sourcing valves, machining pump shafts, or designing structural elements, hardness impacts wear resistance, machinability, formability, and durability. Understanding the basics can help you choose the right stainless grade — and avoid costly mistakes down the line.

At PM International, we regularly help engineers and procurement teams align hardness with application requirements. Here’s what you need to know.

What Is Hardness in Stainless Steel?

Hardness is a material’s ability to resist surface deformation. In simpler terms, the harder the material, the better it resists scratching, denting, or wear.

There are several standard methods to measure hardness in stainless steel:

– Brinell (HB): Often used for castings and forgings; uses a steel or carbide ball

– Rockwell B & C (HRB/HRC): Common in industrial stainless applications

– Vickers (HV): More precise, especially for thin materials or microstructures

Common Hardness Ranges by Stainless Steel Grade

Here’s how some of the most frequently used stainless steels compare:

| Stainless Steel Grade | Condition | Typical Hardness | Application Notes |

|---|---|---|---|

| 304 / 304L | Annealed | HRB 70–90 | Great corrosion resistance, easy to form |

| 316 / 316L | Annealed | HRB 80–90 | Excellent in marine and chemical environments |

| 410 | Hardened / Q&T | HRC 35–45 | Good wear resistance, moderate corrosion |

| 440C | Hardened | HRC 55–60 | Very hard; great for valves, bearings |

| 17-4PH | Heat treated (H900) | HRC 40–44 | Strong + corrosion resistant, aerospace-ready |

Note: Austenitic grades (like 304 and 316) can’t be hardened by heat treatment, but they can be cold worked to increase surface hardness.

Why Stainless Steel Hardness Matters in the Field

– Wear Resistance

Harder stainless steels are better for applications involving friction, impact, or abrasive media. For example, components like pump shafts or valve seats benefit from high hardness to reduce wear and extend service life.

– Machinability

Softer steels (like annealed 304 or 316) are easier to machine, drill, or weld — making them better for complex fabrications or custom builds. Harder steels may require specialized tooling and longer lead times.

– Formability

Lower-hardness steels are also more ductile, which means they’re easier to bend, shape, and cold-form without cracking. This matters when you’re working with press-fit assemblies or high-precision piping.

How to Adjust or Specify Hardness in Stainless Steel

✅ Cold Working (for Austenitic Grades)

Grades like 304 and 316 can’t be hardened by heat, but they can be cold worked — rolled, drawn, or stretched — to increase surface hardness and strength.

✅ Heat Treatment (for Martensitic & PH Grades)

Steels like 410 and 17-4PH respond well to heat treatment. For example:

-17-4PH at H900 delivers excellent strength and moderate hardness

-440C can be hardened to over HRC 55, making it ideal for wear-critical parts

✅ Surface Hardening (Optional)

Processes like nitriding or carburizing can harden the surface layer of stainless parts without affecting core ductility. Useful for shafts, threads, or parts exposed to constant abrasion.

Choosing the Right Hardness for Your Application

Here are a few examples of how hardness influences alloy selection:

– Food-grade tanks or valves? Use 316L — corrosion resistance over hardness

– Pump shafts or bushings? Use 17-4PH or 440C — balance of hardness and strength

– Exposed hardware in a corrosive setting? Don’t over-harden — high hardness can lead to brittleness or stress corrosion cracking

The takeaway: Higher hardness isn’t always better. It’s about the right balance for your specific environment.

Why PM International Clients Trust Us for Stainless Selection

We’ve helped clients across the chemical, marine, power, and pulp & paper industries match the right stainless alloys to their operating conditions.

Our strengths include:

– Stainless forgings, valves, flanges, fittings, and machined parts

– Material options ranging from 304L to 17-4PH to 440C

– Mill Test Reports (MTRs) and full ASTM/NORSOK/EN compliance

– Fast quotes and knowledgeable support for engineers and buyers

Whether you need soft, formable stainless for a high-purity application or ultra-hard material for wear resistance, we can help you source the right alloy — and get it to you on time.

Final Thoughts

Hardness isn’t just a spec — it’s a performance indicator. It affects how your part wears, how it’s made, and how long it lasts in the field. When you understand what it means, you can make better sourcing decisions that improve reliability and reduce cost over time.

👉 Request a Quote or speak with a PM International specialist about stainless alloys that deliver the hardness — and corrosion resistance — your application needs.