Copper Nickel CuNi

UNS C70600 – C70620 – C7060x – C71500 – C71520 – C71640

CuNi 90/10 & CuNi 70/30 Plate/Sheet

CuNi 90/10 & CuNi 70/30 Seamless & Welded Tube

CuNi 90/10 & CuNi 70/30 Seamless & Welded Pipe

CuNi 90/10 & CuNi 70/30 Round Bar

CuNi 90/10 & CuNi 70/30 Flanges

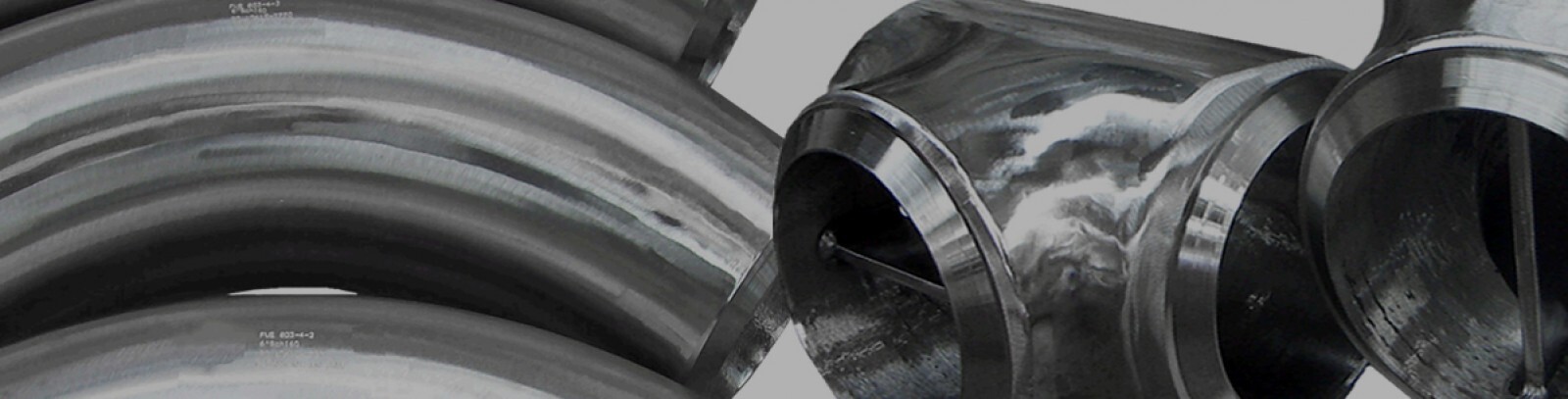

CuNi 90/10 & CuNi 70/30 Seamless & Welded BW Fittings

| Trade Name | UNS | Copper Nickel Industry Specifications | Chemical Composition | Min.Tensile (KSI) | Min.Yield (KSI) | Elongation % |

|---|---|---|---|---|---|---|

| CuNi 90/10 | UNS C70600 UNS C70620 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543 ASTM B111, B122, B151, B171, B359, B395, B432, B466, B467, B543, B608 DIN 2.0872 MIL C-15726, T-15005, T-16420, T-22214 SAE J461, J463 | Cu 88.6 min Pb .05 max* Fe 1.8 max Zn 1 max* Ni 9-11 max Mn 1.0 max | 38 | 15 | 30 |

| CuNi 90/10 | UNS C7060X | EEMUA 144 90/10, 145 90/10, 14 90/1 | Cu rem. Pb .01 max Fe 1.5-2.0 Zn 0.2 max P 0.2 max S 0.2 max Ni 10-11 Mn 0.5-1.0 | 40 | 15 | 30 |

| CuNi 70/30 | UNS C71500 UNS C71520 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543 ASTM B111, B122, B151, B171, B359, B395, B432, B467, B543, B552, B608, F467, F468 DIN 2.0882 MIL C-15726, T-15005, T-16420, T-22214 SAE J461, J463 | Cu(65.0 min) Pb .05 max* Fe 0.4-1.0 Zn 1 max* Ni 29-33 Mn 1 max | 52 | 18 | 45 |

| CuNi 70/30 | UNS C71640 | ASTM B111, B543, B552 | Cu rem Pb .05 max* Fe 1.7-2.3 Zn 1 max* Ni 29-32 Mn 1.5-2.5 | 63 | 25 | -- |

*When the product is subsequent welding applications and so specified by the purchaser, Zn shall be .50% max., Pb .02% max., P .02% max., Sulfur .02% max. and Carbon .05% max.

General Copper Nickel information

Copper Nickel CuNi alloys are alloys of copper and nickel – with or without other elements – where the zinc content may not be more than 1%. Compared with each other element, nickel has the largest individual content after copper when other elements are present. One should distinguish between wrought alloys when considering other copper alloys that are processed to semi-finished products, and cast alloys where castings are produced by various casting processes. The Cu-Ni alloys with additions of manganese are important in electrical engineering. Additions of iron significantly improve the resistance of Cu-Ni alloys to erosion corrosion in flowing seawater and other aggressive waters.

Copper Nickel Applications

- Desalination

- Seawater Piping Systems

Copper Nickel CuNi Corrosion Resistance

Copper alloys provide very good resistance to seawater, brine water, organic compounds, salts, diluted non-oxidizing acids, and more. CuNi 90/10 (C70600 & C7060X) is a Copper nickel iron alloy with a small content of manganese that adds excellent resistance to sea- and brackish water. Of all commercial copper alloys, CuNi 70/30 (C71500) provides the best resistance corrosion in watery environments. It is resistant to acid solutions and highly resistant to stress corrosion cracking, and impingement corrosion. In addition, CuNi 70/30 provides greater strength in higher pressures.

Copper Nickel CuNi Heat Resistance

The hot strength of copper increases with only a small addition of nickel. By adding iron, mechanical properties are improved, not only at room temperature, but also at elevated temperatures. 10% Ni. CuNi10Fe1Mn, for example, can be used in pressure vessel construction up to 300°C, CuNi30Mn1Fe up to 350°C. Above these limit temperatures, strength drops markedly, particularly the creep strength and creep strain limit.

Copper Nickel CuNi Heat Treatment

In general, heat treatments are only used with Cu-Ni alloys for soft annealing and stress relieving. Temperatures for recrystallisation annealing can vary over wide limits between about 620 and 900°C, depending on degree of cold work, nickel content and additional constituents. High temperatures are associated with short annealing times (continuous annealing) and low temperatures with long annealing times (static annealing). Stress-relief annealing is carried out at 280 to 500°C. It is advisable to anneal excluding air or in a slightly reducing atmosphere, to avoid the pickling that is required with air-containing annealing atmospheres.